Khoom Paub meej

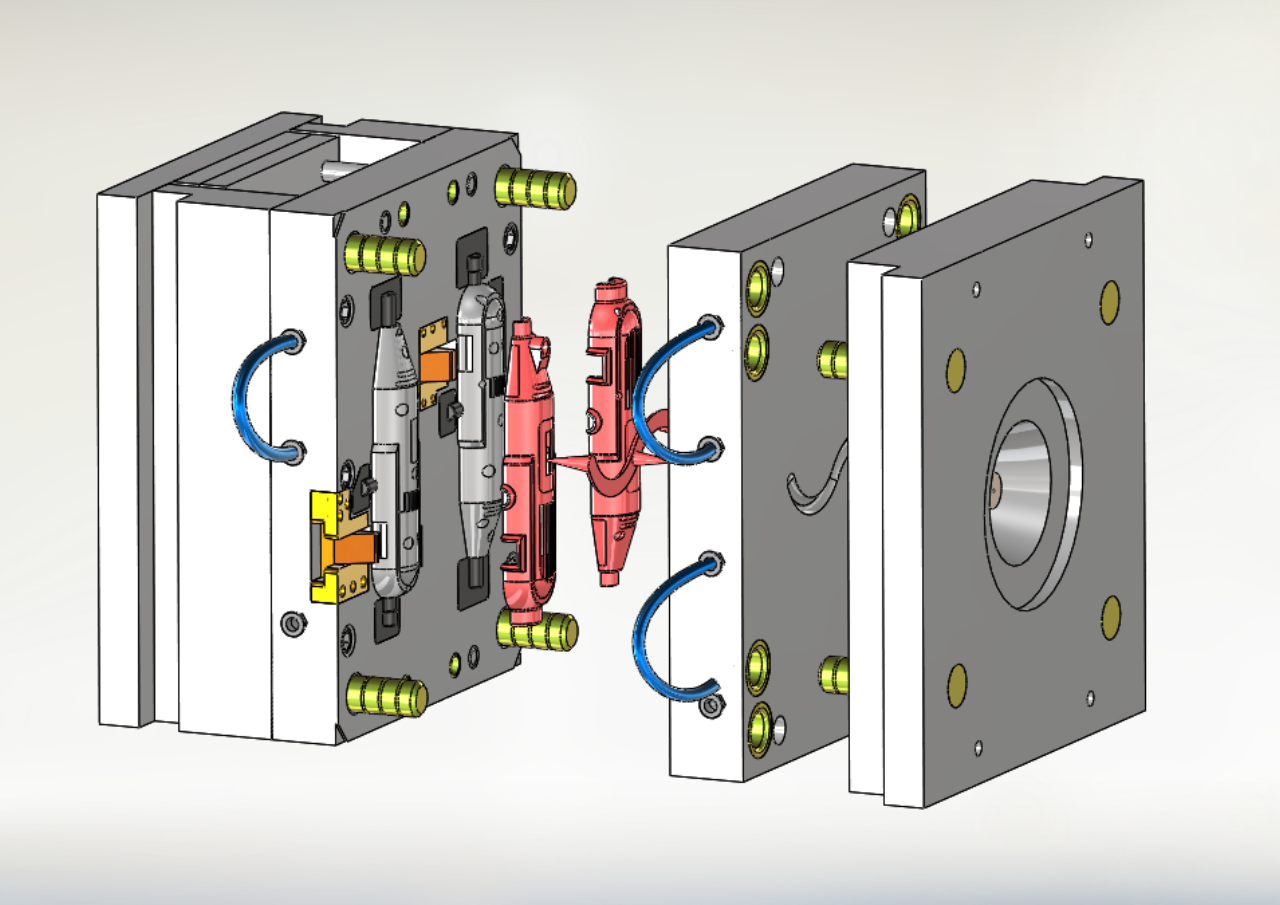

ABS Yas Txhaj Tshuaj Molding Los Ntawm Kev Tsim Nyog Ntawm Nws Cov Khoom Siv Cov Neeg Kho Siab, Los Ntawm Tsim Nyog Pwm Tsim, Los Ntawm Cov Khoom Moulding Kev Ua Tau, Lub Siab Precision Abu Tshuaj Abs Txhaj Tshuaj Molding Khoom.

Kev Cuam Tshuam:ABS Yas Txhaj Tshuaj Molding muaj cov kev cuam tshuam zoo cuam tshuam thiab tswj lub zog zoo thiab muaj kev nruj txawm tias muaj qhov kub tsawg.

Rigidity thiab hardness:ABS Yas Txhaj Tshuaj Molding muaj ntau rigidity thiab hardness thiab tuaj yeem tiv taus loj sab nraud.

Txhuas:ABS Yas Txhaj Tshuaj Molding tseem tuaj yeem tswj tau zoo ua kom tsis kam nyob rau hauv qee qhov kev sib txhuam siab.

Xav paub ntxiv? Xav tias dawb hu rau peb thiab cia txhaj tshuaj molding ntxiv tsis muaj cai rau koj qhov project!

ABS Yas Txhaj Tshuaj Molding Cov Khoom Siv Ua Haujlwm

| Cov Khoom Siv | Kev piav txog |

| Mayt Kub | 220 degree - 250 degree |

| Cov iav hloov cua kub (TG) | 105 degree |

| Ceev | 1. {03 - 1. 20 g / cm³. |

| Kev kub heev | Zoo:Haum rau cov pwm sib tov, cov phab ntsa nyias thiab cov ncauj lus kom ntxaws heev tso tshuaj pleev cov khoom, cov Flowability tso cai rau cov pwm noj qab zib hauv lub sijhawm luv luv. Txo kev txhaj tshuaj kub thiab kev txhaj tshuaj ntau dua yog feem ntau siv los txo cov cim txaus thiab tsis xws luag. |

| Txhaj Tshuaj Tshua | {{0 {0}} bar nyob ntawm qhov ntsuas pom, cov qauv pwm, phab ntsa thickness thiab kev txhaj tshuaj nrawm. Cov ntu nyuaj yuav xav tau kev txhaj tshuaj ntau dua. |

| Txhaj tshuaj tiv thaiv ceev | Nruab nrab sai sai,Nyob ntawm qhov nyuaj ntawm cov khoom thiab qhov loj ntawm kev txhaj tshuaj molding tshuab. Rau ntau txoj kev nyuaj, nyias-walled cov khoom lag luam, ib qho kev txhaj tshuaj tiv thaiv kev nyab xeeb tuaj yeem ua kom tau kev tsim khoom. |

| Pwm kub | 50 DEGREE - 80} degree |

| Lub sijhawm txias | 15 - 30} vib nas this,Nyob ntawm phab ntsa tuab ntawm ib feem, cov pwm kub thiab cov thermal conductivity ntawm cov khoom. Thicker qhov xav tau lub sijhawm txias ntev kom ntseeg tau tias muaj kev ruaj khov ntawm cov pwm. |

| Kev shrinkage | {{0 {0}}. 4% {- 0. 8% yuav sib txawv raws li phab ntsa tuab, pwm tsim, thiab lwm yam. Shrinkage feem ntau yog siab dua rau nyias-walled seem thiab yuav tsum tau saib xyuas tshwj xeeb thaum lub sijhawm pwm tsim. |

| Gloss | Zoo siab:Abs muaj cov nto nto zoo thiab ci, thiab tuaj yeem nthuav tawm cov khoom zoo heev, yog li cov neeg nyob hauv lub ntsej muag, ib yam xov tooj ntawm tes, kuaj tsheb sab hauv). |

| Cov Khoom Siv Neeg Kho Tshuab | Kev Cuam Tshuam:ABS muaj kev cuam tshuam ntau, tshwj xeeb tshaj yog thaum muaj qhov haum kub, thiab haum rau siv nyob rau hauv cov khoom siv-resistant khoom (piv txwv li cov cuab yeej, cov cuab yeej siv tsheb). |

| Rigidity thiab hardness | Nruab nrab hardness,Zoo toughness, tuaj yeem tiv taus cov neeg siv cov khoom siv. Haum rau txhua hnub cov neeg siv khoom thiab cov ntawv thov ntsaws nruab nrab. |

|

Kev Rwb Hluav Taws Xob |

Zoo:ABS muaj hluav taws xob rwb thaiv tsev zog thiab yog qhov haum rau cov khoom siv hluav taws xob tsev, khoom siv hluav taws xob (piv txwv li cov thawv roj teeb hluav taws xob). |

| Thaum Tshav Kub Kub Ua | Nruab nrab:ABS muaj qee cov cua sov tiv thaiv (TG ntawm 105 degree) thiab haum rau siv nyob rau hauv nruab nrab qhov chaw nruab nrab, tsis yog rau kev kub siab ua haujlwm ib puag ncig. Cov kev siv cov ntawv thov uas muaj suav nrog cov khoom siv hauv vaj tsev, incotive interiors, thiab lwm yam. |

| Tshuaj Kuj | Zoo:Abs uas tiv taus cov tshuaj me (xws li roj me (cov kuab tshuaj, kua qaub, thiab lwm yam), tab sis tsis muaj zog rau cov tshuaj muaj zog xws li muaj zog acids thiab alkalis. Nws yog qhov haum rau kev siv nyob rau hauv feem ntau ib puag ncig ib puag ncig thiab cov chaw uas muaj tshuaj lom neeg tsawg. |

| UV Kuj | Zoo:ABS muaj qee qib ntawm UV tiv taus, tuaj yeem siv rau hauv chaw ib sab nraud rau lub sijhawm ntev dua tsis muaj kev laus ntev. Feem ntau siv nyob rau hauv tsev sab nraum zoov, ntu tsheb sab nrauv thiab lwm yam khoom raug rau lub hnub. |

| Kev Ua Haujlwm Tom Qab | Diversification:ABS nto yog haum rau txau, sift-screen luam ntawv, sivij-electradating, laser khij thiab lwm cov txheej txheem tom qab ua kom zoo nkauj thiab ua haujlwm. Tom qab kho, cov khoom tiav tiav yog ntau dua nyob rau hauv txoj kab nrog kev ua lag luam siab kawg. |

| Rov ua tau zoo heev | ABS Yas yog qhov yooj yim rau kev rov qab siv dua thiab tuaj yeem rov qab siv dua rau qee yam. Siv cov khoom lag luam me tuaj yeem siv rau hauv cov khoom lag luam qis, tab sis cov txheej txheem rov ua dua tshiab tuaj yeem cuam tshuam nws lub cev lub cev. |

| Cov chaw thov cov chaw | Automotive:Sab hauv thiab sab nraud txiav seem, ntsuas panels, teeb raws kev cuam tshuam, thiab lwm yam. Cov Khoom Siv Hluav Taws Xob:Cov tsev nyob hauv TV, xov tooj ntawm tes, cov teeb meem roj teeb, thiab lwm yam. Khoom vaj khoom tsev:Tshuab ntxhua khaub ncaws npog lub plhaub, tub yees ntxa, thiab lwm yam. Cov neeg siv khoom lag luam:Cov khoom ua si, khoom siv kis las, khoom siv hauv chaw ua haujlwm, thiab lwm yam. |

Cov txiaj ntsig zoo ntawm ABS yas txhaj tshuaj molding piv nrog PP, PE, PVC

Cov Khoom Siv Raw Khoom Siv

ABS:

Cov khoom siv raw ntawm AB yog feem ntau siab dua li ntawm PP thiab PE, tab sis qis dua li ntawm PVC. Nws yog ib qho luv luv luv luv thiab haum rau siv hauv cov ntawv thov uas yuav tsum tau ua kom zoo dua cov kws kho tshuab, tsos, thiab qee qhov kub tiv thaiv.

Piv rau PP, PE, thiab PVC, ABS feem ntau yog siv los ua cov yas ua tau zoo dua qub, thiab nws cov khoom lag luam, thiab lwm yam khoom lag luam nrog cov khoom muaj txiaj ntsig zoo.

PP, PE:

PP thiab PE yog cov khoom siv yas pheej yig dua, siv tau ntau yam, cov khoom lag luam hauv tsev, cov khoom lag luam uas muaj pov tseg, thiab lwm thaj teb. Lawv tau paub tab cov txheej txheem thiab cov khoom siv raw pheej yig, yog li lawv yog qhov zoo dua nyob rau hauv cov nqe lus, tshwj xeeb tshaj yog rau kev ua lag luam qis thiab cov neeg siv khoom lag luam tsawg.

PVC:

Cov khoom siv raw ntawm pvc feem ntau qis dua li ntawm ABS, tab sis tus nqi yog siab me ntsis siab dua li ntawm PP thiab PE. Cov nqi ntau lawm yuav nce ntxiv vim muaj kev nce qib siab thiab kev ua ntawm PVC, tshwj xeeb tshaj yog qhov yuav tsum tau ntxiv cov tshuab yas thaum ua.

Xaus:ABS yog qhov kim me ntsis piv rau PP thiab PE, tab sis nws cov kev sib xyaw ua ke, tshuaj lom neeg, thiab lwm yam) muab kev txhawb nqa kom tsim nyog rau nws tus nqi. Piv rau PVC, ABS yog tus nqi me dua rau cov ntawv thov ntau nrog cov tsos thiab kev ua tau zoo ..

Lub sijhawm Moulding voj voog thiab ntau lawm kev ua tau zoo

ABS:

Abs muaj qhov tsis tshua muaj kev txhaj tshuaj Molding lub sijhawm, zoo fluidity, thiab muaj peev xwm sau moulds sai sai. Qhov no txhais tau tias nws yog khoom tsim dua thiab tuaj yeem txuag sijhawm, tshwj xeeb yog nyob rau hauv cov khoom moulding ntawm cov seem.

PP, PE:

PP thiab PE muaj qhov tsis tshua muaj kev txhaj tshuaj Molding Cycles thiab cov zoo heev, uas ua rau lawv haum rau kev ua nyias-walled, cov duab sib xyaw. Lawv muaj peev xwm ntau dua hauv cov txheej txheem moulding thiab yog qhov tsim nyog tshwj xeeb rau kev sib ntau ntau.

PVC:

PVC muaj lub voj voog ntxiv moulding thiab tsis tshua muaj khoom lag luam, tshwj xeeb tshaj yog thaum cov yas tau yuav tsum tau ntxiv lossis thaum cov uas yuav tsum muaj. PVC xav tau lub sijhawm txias thiab qeeb qeeb txheej txheem ntau dua li abs.

Xaus:ABS muaj lub voj voog me me pwm, tshwj xeeb tshaj yog tsim nyog rau cov khoom me me thiab qhov ntsuas siab. Thaum PP thiab PE muaj cov voj voog luv luv mycles thiab haum rau huab hwm coj ntau lawm, pvc yog qis dua rau absing ceev.

Pwm Them Thiab Lub Neej

ABS:

Pwm tsis tuaj yeem ua kom ruaj khov thiab cov pwm tsim qauv tsis yog qhov nyuaj ua qee qhov kev ua tau zoo plastics thiab tuaj yeem tiv thaiv kev hnav thiab kua muag ntawm kev tsim khoom ntev. Txawm hais tias pwm nqi ntawm ABS yog siab tshaj li ntawm PP thiab PE, piv rau PVC, nws cov pwm ua PVC, nws cov roj ntsha yog qhov nruab nrab thiab kav zoo dua.

PP, PE:

PP thiab PE muaj cov nqi qis dua thiab feem ntau haum rau tsawg-precision, cov khoom ntim ntau lawm. Cov pwm rau cov plastics no muaj cov yuav tsum muaj qhov yuav tsum muaj ntau dua yog cov kev tiv thaiv ntau dua thiab muaj lub neej muaj kev pab ntau dua.

PVC:

PVC pwm yog qhov cuam tshuam rau kev hnav thiab kua muag, tshwj xeeb tshaj yog thaum siv cov tawv nqaij tawv PVC, thiab cov pwm kim dua los tswj. Raws li qhov tshwm sim, cov nqi pwm thiab kev txij nkawm tuaj yeem ua tau siab dua rau PVC dua li rau ABS PE thiab PP.

Xaus:Txawm hais tias tus nqi ntawm tus ab tuaj pwm me dua li PP thiab PE, lub durability ntawm pwm ua rau lawv muaj txiaj ntsig ntau dua hauv qee yam kev xav tau lag luam. Piv rau PVC, ABS muaj lub neej ntev dua.

Tiav & tsos

ABS:

Cov khoom siv abs muaj cov khoom zoo nkauj zoo nkauj thiab yog yooj yim rau kev ua kom pom tseeb hauv tsev, xws li cov cuab yeej siv hluav taws xob, cov khoom siv hluav taws xob, lwm yam).

PP, PE:

PP thiab PE muaj rougher nto zoo thiab yog qhov nyuaj rau kev ua tshuaj tsuag nrog txau, plating, thiab lwm yam uas lawv tsis haum rau cov khoom lag luam nrog cov tsos.

PVC:

Qhov chaw zoo ntawm pvc feem ntau zoo dua rau ntawm PP thiab PE, tab sis tsis zoo li qhov ABS. PVC tuaj yeem raug rau cov kev khoeg saum npoo xws li luam tawm, txheej, thiab lwm yam.

Xaus:Cov tsos kev kho thiab saum npoo ua tiav ntawm AB yog zoo dua li ntawm PP, PE, thiab PVC, uas yog qhov tsim nyog rau cov khoom lag luam nrog cov kev pom zoo ntawm cov tsos.

Kev ceev faj hauv kev ua cov ABS yas txhaj tshuaj

Tswj Qhov Kub

Injector kub:ABS yog qhov ntsuas kub heev. Lub barrel kub ntawm lub injector yuav tsum tau ceev cia nruab nrab ntawm 220-280 degree thiab cov pwm kub feem ntau khaws cia nruab nrab ntawm {}} degree. Qhov siab dhau los lossis qis dhau qhov kub yuav ua rau thaum lub sijhawm txhaj tshuaj molding, xws li cov tsis xws luag, npuas, deform, deform, thiab lwm yam.

Yaj kub:Dhau ib tug heev melt kub kuj yuav ua rau cov decomposition ntawm cov khoom thiab kev tsim cov ntxhiab tsw, thaum muaj kev cuam tshuam fluidentity thiab ua rau tsis tiav fluidits.

Cua txias txias:Qhov txias txias ntawm cov pwm yuav tsum nyob ruaj khov, thiab qis dua txias yuav ua rau lub ntsej muag txias heev yuav ua rau lub ntsej muag tsis du lossis tsim cov kab nrib pleb.

Txhaj Tshuaj Ceev Thiab Kev Tswj Siab

Txhaj Tshuaj Ceev:Kev Txhaj Tshuaj nrawm yuav ua rau muaj cov pwm nrog cov yas, uas yog nquag ua npuas, ya cov npoo, thiab lwm yam tsis meej; Kev nrawm dhau heev yuav ua rau cov khoom siv tsis zoo, ua rau hauv cov khoom tsis tiav.

Txhaj tshuaj siab:Kev txhaj tshuaj siab yuav tsum tau hloov kho raws li kev tsim qauv ntawm cov pwm, phab ntsa tuab, thiab cov khoom nyuaj. Kev txhaj tshuaj tsis tshua muaj cua siab yuav ua rau cov neeg pluag moulding, thiab siab dhau yuav ua rau tawg lossis deformation ntawm cov khoom nto.

Khoom shrinkage thiab warpage tswj

Shrinkage tswj:Qhov kev txiav tawm ntawm cov khoom abs feem ntau yog nruab nrab 0. 4% {2}}. 8%. Cov yam ntxwv ntsws ntawm cov khoom yuav tsum tau txiav txim siab thaum tsim cov pwm, muaj cov teeb meem tuab heev yuav ua rau muaj cov teeb meem raug.

Warpage Control:Vim yog cov coefficient ntawm thermal expansion ntawm ABS, cov khoom lag luam yog nquag ua warpage thaum txias tom qab molding. Txhawm rau tiv thaiv kev tawm tsam warpage, cov pwm tsim qauv yuav tsum ua kom zoo dua lub txias txias thiab xyuas kom meej tias lub phab ntsa tuab ntawm cov khoom yog khaub ncaws hnav.

Khoom Kev Soj Ntsuam

Tshuaj Ntsuam Xyuas Sab Nrau:Cov khoom lag luam ABS yuav muaj kev hloov pauv hauv lub cev thaum lub sijhawm moulding txheej txheem, thiab yuav tsum tau kuaj cov txheej txheem siv kom ntseeg tau tias cov khoom lag luam tsim cov qauv tsim qauv.

Nto Yuam Kev Soj Ntsuam:Qhov chaw nyob saum npoo tsis zoo yog feem ntau zoo, tab sis xws li npuas, ntws tawm, yuav tseem tshwm sim thaum lub sijhawm tsim khoom thiab raug tshuaj xyuas.

Cov ntaub ntawv ntxaws ntxaws ntxiv hauv qab no

| Cov Khoom Loj | Yas txhaj tshuaj pwm, kev kho mob ib feem pwm, imd, 2k txhaj tshuaj pwm, silicone roj hmab pwm, tuag casting, qauv, cnc milling, cnc Raws ... |

| Cov Hom Ntawv | Solidworks, PRO / Engineer, Auto CAD, PDF, JPG, qauv |

| Yas Khoom | Lub duav ABS, PC, PP, PS, POM, POM, POM, POM, PBT, PBT, PBT, PBT, ABS.ETC |

| Pwm 'cov sijhawm ua | {20-35 hnub, nws nyob ntawm cov khoom loj thiab cov qauv |

| Ntau lawm lub sijhawm | {25-30 hnub, nws nyob ntawm cov khoom loj thiab cov qauv |

| Khoom qhov hnyav hnyav | 1g txog 5000g |

| Pwm Txheej | + / -0. 01 hli |

| Pwm Lub Neej | 300K {{{{{} Kuv txhaj tshuaj, hloov kho pwm dawb |

| Pwm Zos | Ib kab noj hniav, ntau-kab noj hniav. |

| Khiav Tawm Kev Sib Txawv | Kub khiav thiab txias khiav. |

| Cuab tam | 1.Toonging kev txhim kho Machinery: Swiss Mikron High Efficiency machining chaw, Swiss Mikron Kev Kub Ceev Ceev Ntsuas CNC Chaw, Nyij Pap Moulino CNC milling chaw machining chaw, Taiwan Zoo Lub taub hau CNC Machining Chaw, Swiss Sharmilles Edm Machining Chaw, Nyiv Makino EDGE 3S Sinker EDM...2.Component Finishing Machinery: Henghui Sing & Bio-Padding Machine,100,000 Grade Oil Spraying Line... 3.Qhov tshuaj ntsuam Toyery: Toyo siv hluav taws xob txhaj tshuaj molding tshuab Si-tsib, Yizumi Txhaj Tshuab, Dohghua txhaj Tshuab Haitian Machinery, Sumitomo Txhaj Tshuab, Haitian Ob Chav Moulding Tshuab ... |

| Txhaj Tshuaj Tshuab | Raws li cov khoom lag luam kom xaiv tus qauv sib txawv 80T, 120t, 250t, 450t, 800t, 1200T txhaj tshuaj tshuab. |

| Nto Kho | Polishing, pleev xim, chroming, txhuam hniav, kev txhuam hniav, kev txiav plaub hau, ua kom cov tawv nqaij, ua kom huv si, UV pleev xim ... |

| Xim | Dawb, dub, liab, xiav..et. raws li cov neeg yuav tsum tau ua. |

| Kev kuaj xyuas | 100% kev tshuaj xyuas los ntawm QC, QA ua ntej xa khoom. |

| Cov Ntawv Thov | Txhua hom tsheb spare tshooj, machinery, cov khoom hauv tsev, cov khoom siv kho mob, cov cuab yeej siv hluav taws xob, cov khoom siv hluav taws xob, kho vajtse thiab cov khoom siv yas, khoom siv kis las thiab Khoom plig, thiab ntau dua. |

| Kev tswj kom zoo | ISO9001 Kev Tswj Xyuas Kev Tswj Xyuas Zoo. |

| Lub thawv | Raws li cov neeg yuav tsum tau ua |

Peb Cov Kev Pab

Txhaj Tshuaj Molding Tsim & Engineering

1.Pwm Tsim Nrog 4 Cov Kws Ua Haujlwm nrog 5-10} xyoo ntawm kev paub

2.3D khoom ua qauv

3.Kev yoog raws cov txheej txheem tsis

4.Kev Tshawb Xyuas Pwm

Txhaj Tshuaj Molding Ua

1.Hauv-Tsev Ua Pwm Siv thiab tsim khoom ("peb tsis outsource!")

2.100+ ntiaj teb-chav kawm precision cov chaw

3.Tev ntawm ± 0. 001 hli

4.ISO 9001 Ntawv Pov Thawj

Cov Khoom Siv Yas Ntau Lawm

1.20+ 35} tons - 1200} tons Txhaj Tshuaj Molding Machine

2.Ntau pua ntawm cov ntaub ntawv thermopicastic los xaiv los ntawm

3.Kev tswj nruj ua kom nruj: IQC, IPQC, FQC

4.Customized ntim thiab ntim khoom tom qab txhaj tshuaj molding

Qhov Zoo Ntawm Kev Txhaj Tshuaj Molding Qhov

Sai sai Protototyping:Lub sijhawm luv luv voj voog uas txhaj tshuaj molding yog tsim nyog rau kev ua lag luam ntau lawm, thiab tuaj yeem ua tiav cov khoom lag luam ntawm cov khoom lag luam luv.

Lub siab degree ntawm automation:Kev rho tawm cov kab ntau lawm tuaj yeem txhim kho kev ua haujlwm zoo thiab txo cov nqi ua haujlwm.

Chav tsawg nqi:Rau huab hwm coj ntau lawm, tus nqi hauv tsev yog txo qis.

Cov khoom siv siab siv:Cov khoom siv tsawg hauv cov yas txhaj tshuaj molding txheej txheem, thiab cov trimmings tuaj yeem rov ua dua tshiab.

Cov qib siab ntawm kev luam tawm:Ua rau cov khoom lag luam ntau lawm nrog cov duab nyuaj thiab qhov ntev zoo, xws li cov khoom kom ntxaws thiab cov qauv sab hauv.

Ib-thooj Moulding:Enables ua tiav kev sib xyaw ua ke ntawm cov chaw, txo kev sib dhos thiab ua cov kauj ruam.

Siab Precision:Kev txhaj tshuaj cov khoom siv muaj qhov tseeb ntawm qhov tseeb thiab kev sib thooj, ua rau lawv tsim nyog rau kev tsim cov khoom lag luam siab zoo thiab cov neeg siv khoom lag luam.

Xaiv cov khoom siv Raw:Ntau cov ntaub ntawv yas tau ua tiav (piv txwv li ABS, PP, PP, PC, thiab lwm yam.)

Cov Xim Xaiv:Ntau cov khoom sib xyaw ua ke (ob-xim txhaj tshuaj molding los yog ntau cov khoom siv txhaj tshuaj moulding) tuaj yeem ua tiav rau cov khoom qub.

Cov Kev Xaiv Nto:Kev txhaj tshuaj molding tuaj yeem ua tiav ntau yam kev cuam tshuam nrog kev cuam tshuam nrog, xws li du, textured, tsis muaj kev ua tiav.

Qhov tsis zoo ntawm kev txhaj tshuaj molding qhov chaw

Kim siv pwm:Pwm tsim qauv thiab cov nqi tsim khoom yog qhov siab, tshwj xeeb yog cov pwm lossis ntau cov kab noj hniav pwm.

Kev nqis peev loj hauv cov khoom siv: txhaj tshuaj molding tshuab thiab lwm cov khoom siv yog kim, tshwj xeeb tshaj yog cov cuab yeej siv hluav taws xob siab.

Cov Pwm Tsheb Ntev:Pwm Raug Yuav Tsum Muaj Lub Sij Hawm Rau Lub Sijhawm, uas yuav txuas ntxiv cov khoom tsim kho cov khoom.

Cov khoom lag luam kom haum:Cov khoom tsim thiab pwm yuav tsum tau tshaj, thiab yuav tsum tau rov ua kom pom tseeb thiab ua kom zoo dua nyob rau hauv thaum ntxov theem.

Tsis muaj khoom siv meej:Tsis yog txhua cov ntaub ntawv tsim nyog rau kev txhaj tshuaj moulding (piv txwv li cov thermoset plastics thiab cov khoom kub siab).

Dormation pheej hmoo:Cov txheej txheem yog xav tau rau nyias-walled thiab cov khoom loj, uas yuav ua rau warping, shrinkage, thiab lwm yam tsis xws luag.

Ua Parameter pheej hmoo:Cuam tshuam los ntawm cov txheej txheem tsis (piv txwv li kub, lub siab ceev nrawm), cov txheej txheem no yog qhov tsis muaj peev xwm ua kom muaj kev tiv thaiv zoo li no, thiab lwm yam, thiab yuav tsum tswj hwm cov txheej txheem nruj.

Kev pheej hmoo ntawm pwm tsim:Cov tsis raug cai pwm tsim qauv yuav ua rau lub neej luv luv lossis cov khoom lag luam qis dua.

High-ntim kev vam khom:Tsis haum rau cov khoom ntim tsawg, raws li tus nqi ntawm pwm tuaj yeem ua rau cov nqi tsev siab thaum kis tau tsawg tus naj npawb ntawm cov khoom.

Cov Khoom Siv Raw Raw:Qee cov ntaub ntawv yas yog tsis-biodegradable thiab lub resting khib yuav ua rau ib puag ncig.

Ib puag ncig kev pheej hmoo:Kev txhaj tshuaj molding yuav muab cov tshuaj sib ntxiv rau tshuaj lossis kev tawm ntawm cov khoom muaj kev phom sij.

Muaj cov xwm txheej muaj feem xyuam

Haum rau kev txhaj tshuaj molding scoritios

Cov khoom lag luam uas yuav tsum muaj cov txheej txheem siab thiab cov txheej txheem nyuaj (piv txwv, cov khoom hluav taws xob, cov khoom siv tshuaj kho mob).

Cov khoom tsim loj-tsim (piv txwv li cov chaw tsheb, cov khoom lag luam txhua hnub).

Cov khoom lag luam uas muaj qhov xav tau ntawm cov tsos (piv txwv cov neeg siv khoom hauv tsev).

Tsis muaj feem xyuam los txhaj tshuaj molding cov xwm txheej

Me-ntau, customized ntau lawm.

Cov khoom lag luam uas cov khoom nyoos tsis muaj cov qauv ib puag ncig

Cov khoom lag luam nrog cov khoom siv rhiab lossis cov nqi pwm.

Cov Lus Qhia Cov Ntaub Ntawv Tshaj Tawm Cov Ntawv

| Khoom | Pom zoo phab ntsa Thickness [mm] | Pom zoo phab ntsa tuab [ntiv tes] |

| Polypropylene (pp) | {{0 {0}}. {8 - 3. 8 hli | 0.03'' - 0.15'' |

| Abs | 1. {2 - 3. 5 hli | 0.045'' - 0.14'' |

| Polyethylene (PE) | {{{{{0}}}. 8 - 3. 0 hli | 0.03'' - 0.12'' |

| Polystyrene (PS) | 1. {{0 - 4. {0 hli | 0.04'' - 0.155'' |

| Polyurethane (Pur) | 2. {{0 - 20. 0 hli | 0.08'' - 0.785'' |

| Nylon (PA 6) | {{{{{0}}}. 8 - 3. 0 hli | 0.03'' - 0.12'' |

| Polycarbonate (PC) | 1. {{0 - 4. {0 hli | 0.04'' - 0.16'' |

| PC / ABS | 1. {2 - 3. 5 hli | 0.045'' - 0.14'' |

| Pom (delrin) | {{{{{0}}}. 8 - 3. 0 hli | 0.03'' - 0.12'' |

| Qab nkaub | 1. {{0 - 3. {0 hli | 0.04'' - 0.12'' |

| Silicone | 1. {{0 - 10. {0 hli | 0.04'' - 0.40'' |

Khoom Rooj Qhia Khoom

Starway Lub Zog Zog

Peb Kev Pabcuam Pub Dawb: {+86 15821850866

13

lub yim

Peb tau ua haujlwm hauv kev lag luam txij xyoo 2011

5

Pab pawg

Peb muaj 5 pab pawg uas yog pab neeg tsim kev lag luam tsim, 4 zaug ua haujlwm ua haujlwm, pab pawg yuav khoom, thiab pab pawg tsim kho kom zoo, thiab ib pab neeg tsim khoom zoo.

3

Hnub Ua Si

Peb tuaj yeem ua rau cov khoom lag luam hauv cov khoom lag luam tsawg li 3 hnub

Yog tias koj txaus siab rau peb cov khoom lossis koj xav ua thiab kho cov khoom lag luam, thov koj xav tiv tauj peb.

Cim npe nrov: ABS Yas Txhaj Tshuaj Molding, Tuam Tshoj ABS yas txhaj tshuaj molding manufacturers, lwm tus neeg, Hoobkas