Khoom Paub meej

Tus qauv tsim thiab tsim tau zoo ntawm kev txhaj tshuaj pwm ncaj qha txiav txim siab cov khoom thiab cov khoom lag luam zoo yog 500,000 ~ 1,000,000 pwm lub sijhawm. Tus nqi ntawm ib qho khoom lag luam tuaj yeem txo qis los ntawm ib qho kev tsim khoom pwm.

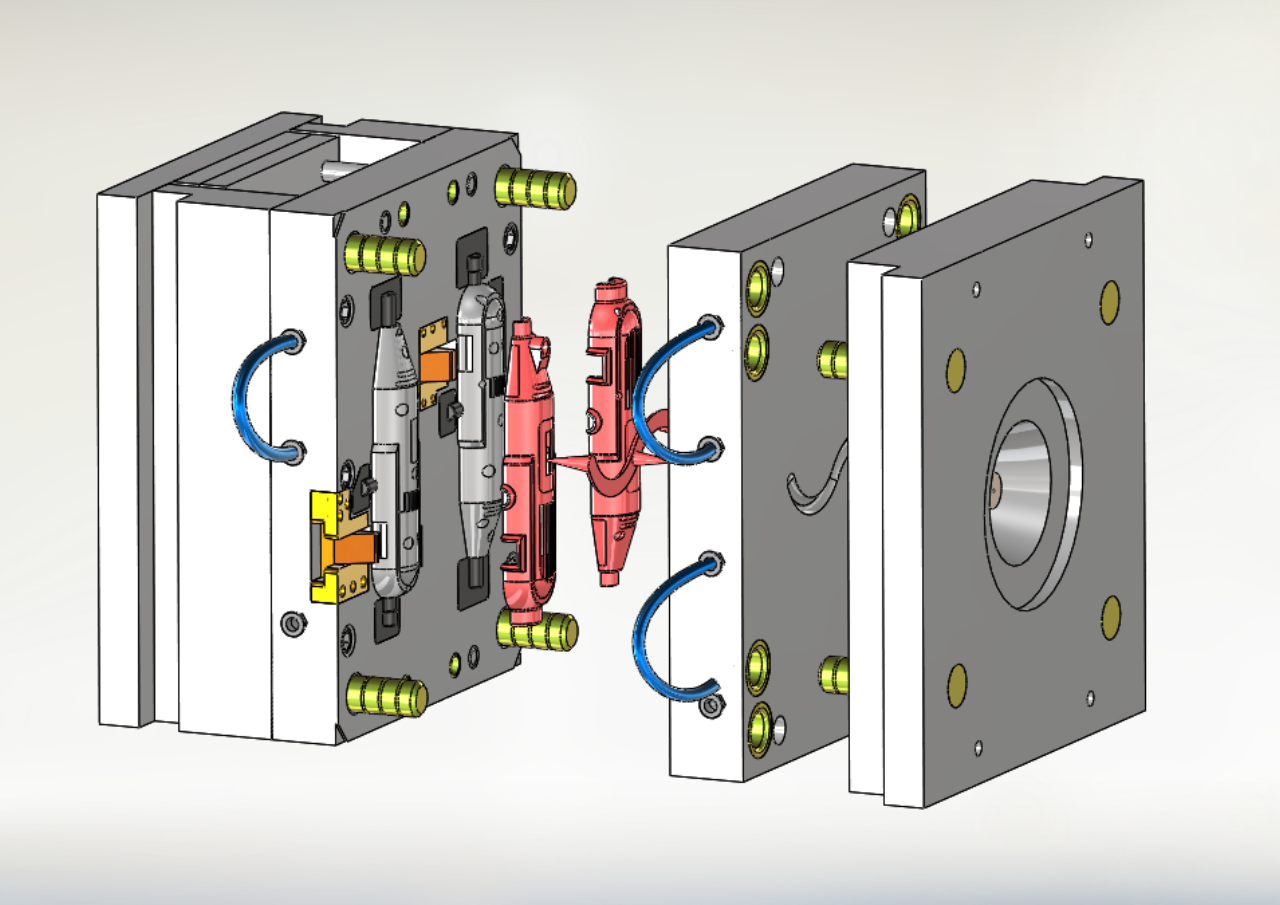

Cov qauv txheej txheem ntawm kev txhaj tshuaj pwm:

Pwm Txom Nyem thiab Cores:Txheeb xyuas cov qauv sab nraud thiab sab hauv ntawm cov khoom.

Pouring System:CARTRIBEUMED cov yas uas muaj tusyees rau hauv cov pwm kab noj hniav.

Cua Txias Zog:Pab molten yas kom txias sai sai rau molding.

Txhim Kho Txheej Txheem:Ejects cov khoom lag luam thiab ua tiav cov kev tsim khoom ntau lawm.

Xav paub ntxiv? Xav tias dawb hu rau peb thiab cia txhaj tshuaj molding ntxiv tsis muaj cai rau koj qhov project!

Qhov tseem ceeb hauv kev txhaj tshuaj molding Tool Tsim

Cov khoom lag luam

1.Cov khoom lag luam loj, cov qauv, thiab kev ua haujlwm tau.

2.Cov khoom yuav tsum tau ua zoo (piv txwv li ci, kev ntxhib los mos).

Cov khoom siv xaiv

Cov khoom ntawm cov ntaub ntawv yas xws li fluinity, shrinkage, thiab siab - kub tsis kam.

Pwm Lub Neej

1.Hnav tsis kam thiab hardness ntawm pwm cov khoom (piv txwv li P20, H13, thiab lwm yam).

2.Cov txheej txheem kho deg (piv txwv li Chrome plating, nitriving) kom txuas ntxiv lub neej pabcuam.

Kev Ua Haujlwm Tshwj Xeeb

Nco ntsoov precision haum ntawm cov pwm seem kom tsis txhob muaj qhov tsis xws luag xws li ya cov npoo thiab kev ua rog ntawm cov khoom lag luam.

Cua txias ua tau zoo

Cua txias zog kev tsim qauv ncaj qha cuam tshuam nrog lub sijhawm molding thiab ntau lawm.

Kev ua tau zoo

Txawm hais tias yuav siv mult - Cavity Cegity Tsim, Kev Siv Hluav Taws Xob Txhim Kho, thiab lwm yam Los txhim kho ntau lawm ceev.

Txhaj tshuaj molding nruab nrab kev pab cuam lub neej

| Pwm Hom Nruab Nrab | Txhuas Mould |

| Ordin Hlau Hlau Pwm | 500,000 ~ 1,000,000 tus tuag |

| Zoo Tshaj Hlau Pwm | 1,000,000 ~ 2,000,000 tus tuag thiab saum toj no |

| Txhuas Mould | 10,000 ~ 100,000 tus tuag |

Cov ntaub ntawv ntxaws ntxaws ntxiv hauv qab no

| Cov Khoom Loj | Yas txhaj tshuaj pwm, kev kho mob ib feem pwm, imd, 2k txhaj tshuaj pwm, silicone roj hmab pwm, tuag casting, qauv, cnc milling, cnc Raws ... |

| Cov Hom Ntawv | Solidworks, PRO / Engineer, Auto CAD, PDF, JPG, qauv |

| Yas Khoom | Lub duav ABS, PC, PP, PS, POM, POM, POM, POM, PBT, PBT, PBT, PBT, ABS.ETC |

| Pwm 'cov sijhawm ua | 20-35days, nws nyob ntawm cov khoom loj thiab qauv |

| Ntau lawm lub sijhawm | 25-30days, nws nyob ntawm cov khoom loj thiab qauv |

| Khoom qhov hnyav hnyav | 1g txog 5000g |

| Pwm Txheej | +/- 0.01mm |

| Pwm Lub Neej | 300K-500k txhaj, hloov pwm pwm dawb |

| Pwm Zos | Ib kab noj hniav, ntau - kab noj hniav. |

| Khiav Tawm Kev Sib Txawv | Kub khiav thiab txias khiav. |

| Cuab tam | 1.Toonging kev txhim kho Machinery: Swiss Mikron High Efficiency machining chaw, Swiss Mikron Kev Kub Ceev Ceev Ntsuas CNC Chaw, Nyij Pap Moulino CNC milling chaw machining chaw, Taiwan Zoo Lub taub hau CNC Machining Chaw, Swiss Sharmilles Edm Machining Chaw, Nyiv TEAMELGE COOS 3S Togter Edm ... Hephui Hu & Bio- Padding Tshuab, 100,000 Qeb Roj Roj Txau Kab ... 3.Qhov tshuaj ntsuam Toyery: Toyo Puab Kev Txhaj Tshuaj Molding Tshuab Si {}} tsib, yizumi txhaj tshuab, Dohghua txhaj Tshuab Haitian Machinery, Sumitomo Txhaj Tshuab, Haitian Ob Chav Moulding Tshuab ... |

| Txhaj Tshuaj Tshuab | Raws li cov khoom lag luam kom xaiv tus qauv sib txawv 80T, 120t, 250t, 450t, 800t, 1200T txhaj tshuaj tshuab. |

| Nto Kho | Polishing, pleev xim, chroming, txhuam hniav, kev txhuam hniav, kev txiav plaub hau, ua kom cov tawv nqaij, ua kom huv si, UV pleev xim ... |

| Xim | Dawb, dub, liab, xiav..et. raws li cov neeg yuav tsum tau ua. |

| Kev kuaj xyuas | 100% kev tshuaj xyuas los ntawm QC, QA ua ntej xa khoom. |

| Cov Ntawv Thov | Txhua hom tsheb spare tshooj, machinery, cov khoom hauv tsev, cov khoom siv kho mob, cov cuab yeej siv hluav taws xob, cov khoom siv hluav taws xob, kho vajtse thiab cov khoom siv yas, khoom siv kis las thiab Khoom plig, thiab ntau dua. |

| Kev tswj kom zoo | ISO9001 Kev Tswj Xyuas Kev Tswj Xyuas Zoo. |

| Lub thawv | Raws li cov neeg yuav tsum tau ua |

Peb Cov Kev Pab

Txhaj Tshuaj Molding Tsim & Engineering

1.Tuaj pwm nrog 4 tus engineers nrog 5-10 xyoo ntawm kev paub

2.3D khoom ua qauv

3.Kev yoog raws cov txheej txheem tsis

4.Kev Tshawb Xyuas Pwm

Txhaj Tshuaj Molding Ua

1.Hauv -} Lub tsev pwm ua thiab tsim khoom ("peb tsis outsource!")

2.{{0100+ ntiaj teb -}} chav thev naus laus zis

3.Thev tau ntawm ± 0.001 hli

4.ISO 9001 Ntawv Pov Thawj

Cov Khoom Siv Yas Ntau Lawm

1.20+ 35} tons - 1200} tons Txhaj Tshuaj Molding Machine

2.Ntau pua ntawm cov ntaub ntawv thermopicastic los xaiv los ntawm

3.Kev tswj nruj ua kom nruj: IQC, IPQC, FQC

4.Customized ntim thiab ntim khoom tom qab txhaj tshuaj molding

Hom Tshuaj Molding Pwm:

-

Cais los ntawm tus naj npawb ntawm cov pwm kab noj hniav:

-

Sing - kab noj hniav puab:Moulding ib yam khoom nyob rau ib lub sijhawm, haum rau me me batches lossis siab - precision cov khoom.

-

Ntau - kab noj hniav puab:Moulding ntau yam khoom nyob rau ib lub sijhawm, txhim kho ntau lawm kev ua haujlwm, haum rau huab hwm coj ntau lawm.

-

-

Tso cais los ntawm pwm qauv:

-

Ob tug phaj pwm:Cov qauv yooj yim, haum rau cov khoom yas yas.

-

Peb {- platen pwm:increase the separation function of the pouring system, suitable for complex products or multi-point feeding.

-

-

Tso cai los ntawm daim ntawv thov:

-

Kub khiav pwm:Txo cov khib nyiab thiab txhim kho kev ua haujlwm molding ua haujlwm los ntawm cov cua sov cov khiav ceev.

-

Khaub thuas khiav pwm:Cov tshuaj pwm, yog tus nqi qis dua, tab sis tsim ntau seem.

-

Tus qauv ntawm kev txhaj tshuaj moulding pwm:

-

Lub ntsiab ntawm cov pwm:

Dynamic thiab tsau pwm:Cov pwm muaj cov qauv yas (mounted ntawm cov ciav hlau txav ntawm kev txhaj tshuaj molding tshuab) thiab ib qho chaw ruaj khov), uas raug kaw los tsim cov pwm kab noj hniav.-

Kab noj hniav thiab tub ntxhais:Cov kab noj hniav txiav txim siab cov duab ntawm cov khoom lag luam thiab cov tub ntxhais tseem ua rau cov qauv sab hauv ntawm cov khoom.

-

Pouring System:Xws li cov chaw ntws ntws loj, manifolds, rooj vag, thiab cov hnab looj ntsej muag, uas tau siv los thauj cov yas yaj mus rau hauv cov pwm kab noj hniav.

-

Cua Txias Zog:Pab cov molten cov yas kom muaj zog thiab pwm tau sai dhau los ntawm cov dej txias.

-

Tso tawm hauv:Txos cua lossis yaj roj los ntawm cov pwm kab noj hniav kom tsis txhob muaj qhov tsis xws luag.

-

Txhim Kho Txheej Txheem:suav nrog ejector pins, thawb daim hlau, thiab lwm yam, siv los tshem cov khoom lag luam me me los ntawm cov pwm.

-

-

Ntu Qauv Qauv:

-

Qhia Cov Pillar thiab coj Bushings:Xyuas kom meej cov kev sib ncag qhov tseeb ntawm kev txav chaw thiab tsau tuaj pwm.

-

Pwm luj:Txhim kho thiab txhawb nqa cov khoom sib xyaw ua ke, muab lub zog thiab kev ruaj khov.

-

Qhov Zoo Ntawm Kev Txhaj Tshuaj Molding Cov Huab Cua

Sai sai Protototyping:Lub sijhawm luv luv voj voog uas txhaj tshuaj molding yog tsim nyog rau kev ua lag luam ntau lawm, thiab tuaj yeem ua tiav cov khoom lag luam ntawm cov khoom lag luam luv.

Lub siab℃ntawm automation:Kev rho tawm cov kab ntau lawm tuaj yeem txhim kho kev ua haujlwm zoo thiab txo cov nqi ua haujlwm.

Chav tsawg nqi:Rau huab hwm coj ntau lawm, tus nqi hauv tsev yog txo qis.

Cov khoom siv siab siv:Cov khoom siv tsawg hauv cov yas txhaj tshuaj molding txheej txheem, thiab cov trimmings tuaj yeem rov ua dua tshiab.

Cov qib siab ntawm kev luam tawm:Ua rau cov khoom lag luam ntau lawm nrog cov duab nyuaj thiab qhov ntev zoo, xws li cov khoom kom ntxaws thiab cov qauv sab hauv.

Ib -} daim molding:Enables ua tiav kev sib xyaw ua ke ntawm cov chaw, txo kev sib dhos thiab ua cov kauj ruam.

Siab Precision:Kev txhaj tshuaj cov khoom siv muaj qhov tseeb qhov tseeb thiab kev sib thooj, ua rau lawv haum rau kev tsim khoom siab thiab cov neeg siv khoom lag luam.

Xaiv cov khoom siv Raw:Ntau cov ntaub ntawv yas tau ua tiav (piv txwv li ABS, PP, PP, PC, thiab lwm yam.)

Cov Xim Xaiv:Ntau cov khoom sib xyaw ua ke (ob {- Kev txhaj tshuaj molding los yog ntau {} Cov khoom txhaj tshuaj molding) tuaj yeem ua tiav rau cov khoom qub.

Cov Kev Xaiv Nto:Kev txhaj tshuaj molding tuaj yeem ua tiav ntau yam kev cuam tshuam nrog kev cuam tshuam nrog, xws li du, textured, tsis muaj kev ua tiav.

Qhov tsis zoo ntawm kev txhaj tshuaj molding plastics

Kim siv pwm:Pwm Tsim thiab cov nqi tsim khoom yog qhov siab, tshwj xeeb yog cov pwm lossis ntau {{} txey kab noj pwm.

Kev nqis peev loj hauv cov khoom siv: txhaj tshuaj molding: txhaj tshuaj molding tshuab thiab lwm cov khoom siv tau kim, tshwj xeeb tshaj yog high - precision khoom.

Cov Pwm Tsheb Ntev:Pwm Raug Yuav Tsum Muaj Lub Sij Hawm Rau Lub Sijhawm, uas yuav txuas ntxiv cov khoom tsim kho cov khoom.

Cov khoom lag luam kom haum:Cov khoom tsim thiab pwm yuav tsum tau tshaj, thiab yuav tsum tau rov ua kom pom tseeb thiab ua kom zoo dua nyob rau hauv thaum ntxov theem.

Tsis muaj khoom siv meej:Tsis yog txhua cov ntaub ntawv tsim nyog rau kev txhaj tshuaj moulding (piv txwv li cov thermoset plastics thiab siab- cov ntaub ntawv kub).

Dormation pheej hmoo:Cov txheej txheem yog xav tau rau nyias -} {{1} - Cov khoom siv cov khoom me, uas yuav ua rau warping, shrinkage, thiab lwm yam tsis xws luag.

Ua Parameter pheej hmoo:Cuam tshuam los ntawm cov txheej txheem tsis (piv txwv li kub, lub siab ceev nrawm), cov txheej txheem no yog qhov tsis muaj peev xwm ua kom muaj kev tiv thaiv zoo li no, thiab lwm yam, thiab yuav tsum tswj hwm cov txheej txheem nruj.

Kev pheej hmoo ntawm pwm tsim:Cov tsis raug cai pwm tsim qauv yuav ua rau lub neej luv luv lossis cov khoom lag luam qis dua.

High - Tsis muaj nyob ntawm:Tsis haum rau tsawg - nplej tshuab ntau lawm, raws li tus nqi pwm tuaj yeem ua rau cov nqi tsev siab thaum kis tau cov khoom me me.

Cov Khoom Siv Raw Raw:Qee cov ntaub ntawv yas tsis yog - biodegradable thiab lub resting pov tseg tej zaum yuav ua rau ib puag ncig.

Ib puag ncig kev pheej hmoo:Kev txhaj tshuaj molding yuav muab cov tshuaj sib ntxiv rau tshuaj lossis kev tawm ntawm cov khoom muaj kev phom sij.

Muaj cov xwm txheej muaj feem xyuam

Haum rau kev txhaj tshuaj molding scoritios

Cov khoom lag luam uas yuav tsum muaj cov txheej txheem siab thiab cov txheej txheem nyuaj (piv txwv, cov khoom hluav taws xob, cov khoom siv tshuaj kho mob).

Mass -}}}} saduces seem (piv txwv li cov tsheb tsheb, cov khoom lag luam txhua hnub).

Cov khoom lag luam uas muaj qhov xav tau ntawm cov tsos (piv txwv cov neeg siv khoom hauv tsev).

Tsis muaj feem xyuam los txhaj tshuaj molding cov xwm txheej

Me - lias, tsim ntau lawm.

Cov khoom lag luam uas cov khoom nyoos tsis muaj cov qauv ib puag ncig

Cov khoom lag luam nrog cov khoom siv rhiab lossis cov nqi pwm.

Cov Lus Qhia Cov Ntaub Ntawv Tshaj Tawm Cov Ntawv

| Khoom | Pom zoo phab ntsa Thickness [mm] | Pom zoo phab ntsa tuab [ntiv tes] |

| Polypropylene (pp) | 0.8 - 3.8 hli | 0.03'' - 0.15'' |

| Abs | 1.2 - 3.5 hli | 0.045'' - 0.14'' |

| Polyethylene (PE) | 0.8 - 3.0 hli | 0.03'' - 0.12'' |

| Polystyrene (PS) | 1.0 - 4.0 hli | 0.04'' - 0.155'' |

| Polyurethane (Pur) | 2.0 - 20.0 hli | 0.08'' - 0.785'' |

| Nylon (PA 6) | 0.8 - 3.0 hli | 0.03'' - 0.12'' |

| Polycarbonate (PC) | 1.0 - 4.0 hli | 0.04'' - 0.16'' |

| PC / ABS | 1.2 - 3.5 hli | 0.045'' - 0.14'' |

| Pom (delrin) | 0.8 - 3.0 hli | 0.03'' - 0.12'' |

| Qab nkaub | 1.0 - 3.0 hli | 0.04'' - 0.12'' |

| Silicone | 1.0 - 10.0 hli | 0.04'' - 0.40'' |

Khoom Rooj Qhia Khoom

Starway Lub Zog Zog

Peb Kev Pabcuam Pub Dawb: {+86 15821850866

13

lub yim

Peb tau ua haujlwm hauv kev lag luam txij xyoo 2011

5

Pab pawg

Peb muaj 5 pab pawg uas yog pab neeg tsim kev lag luam tsim, 4 zaug ua haujlwm ua haujlwm, pab pawg yuav khoom, thiab pab pawg tsim kho kom zoo, thiab ib pab neeg tsim khoom zoo.

3

Hnub Ua Si

Peb tuaj yeem ua rau cov khoom lag luam hauv cov khoom lag luam tsawg li 3 hnub

Yog tias koj txaus siab rau peb cov khoom lossis koj xav ua thiab kho cov khoom lag luam, thov koj xav tiv tauj peb.

Cim npe nrov: Txhaj Tshuaj Pwm Uas, Tuam Tshoj Txhaj Puab Nplaum Chaw Tsim Tshuaj, Chaw muag khoom, Hoobkas